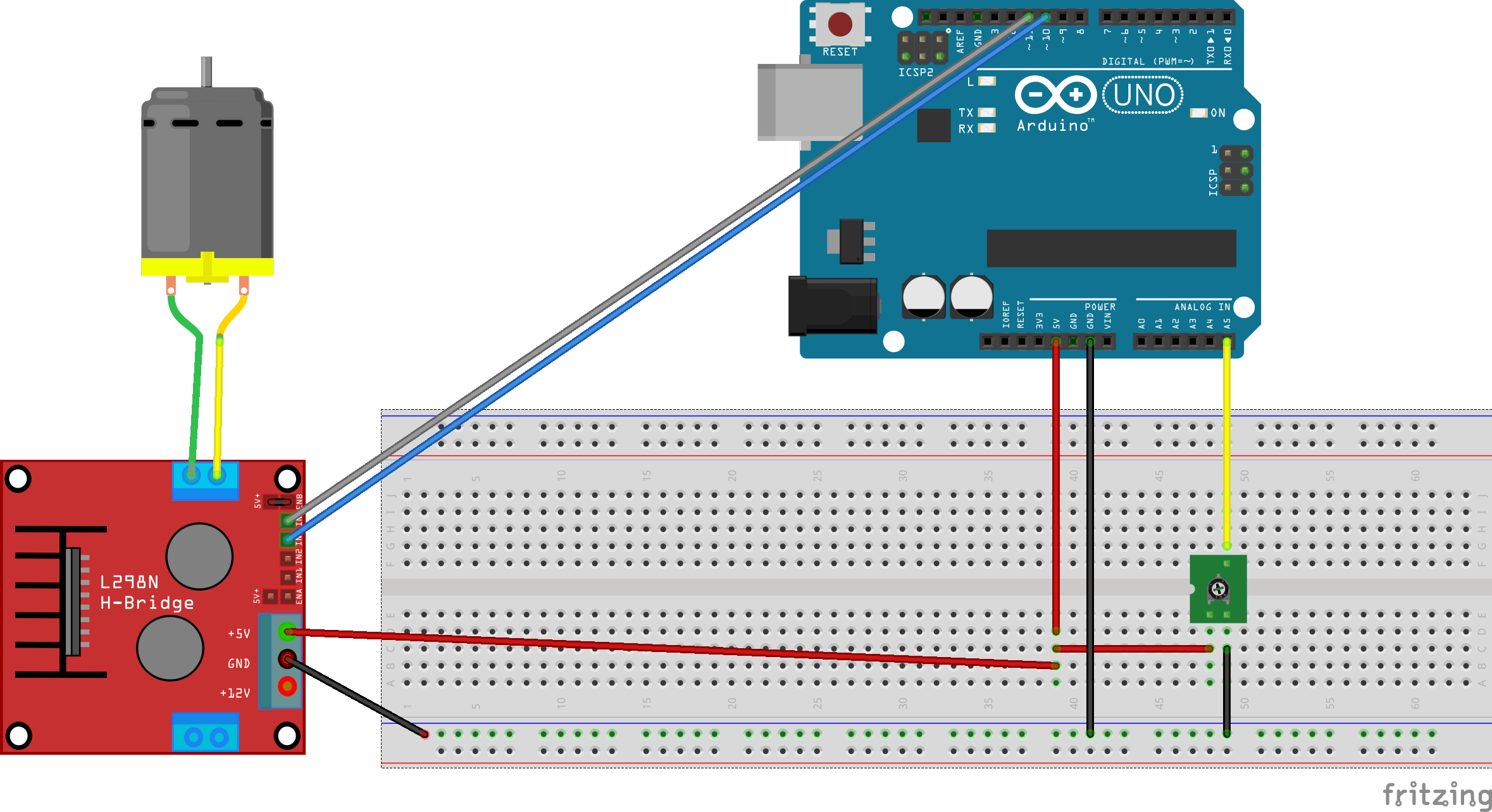

The DiyServo service is a service that can be used as a normal servo, but it's built from a motor and an analog input. The idea is that you should be able to use any motor and any analog input to byild your own servo. The circuit below can be used to connect the motor and the servo to a single Arduino. But it's also possible to configure in alternate ways.

Please note that from version 1.0.2274, the configuraion of the DiyServo is different from earlier versions. It now starts a Motor / MotorDualPwm service as a layer between the DiyServo service and the Arduino.

I made two different scripts to show some alternate configurations.

[[/service/DiyServo.py]]

[[/service/DiyServo2.py]]

I just love it !!! Thanks

I just love it !!!

Thanks guys for this fantastic MRL service.

I have been dreaming of this, ever since I burned my first servo!!

Turn left or right

Thanks your code is very usefull, thanks a lot. But it commands only the speed. How can we command the way ? In other words turn left or turn right with a middle point ? (it exists potentiometer with middle point. I 'm shure of this.) In fact we need both speed and way left or right.

Thanks

Friendly.

Sylvain.

DiyServo

In the example I only have the motor out to show that it works.

Kwatters built the complete DiServo as you can see int his post. So it works in both directions and you can use it just like any other servo. But you have to mount the pot, so that it turns with the joint.

http://myrobotlab.org/content/diy-servo-service

----

If you built one and only can control speed, then you need a different motor control board.

If you for example use that board from the drill, then it will only move in one direction and only control speed.

I use a BTS7960B that I bought from here.

http://www.ebay.com/itm/191833193918?_trksid=p2057872.m2749.l2649&ssPag…

I also use a IBT-4 board from here:

http://www.ebay.com/itm/182073487693?_trksid=p2057872.m2749.l2649&ssPag…

I tested the drillmotor with a LN298N board, but it was not powerful enough.

I also tried this board, but it could only drive the motor in one direction:

http://www.ebay.com/itm/6V-24V-10A-DC-Motor-Speed-Driver-PWM-Adjustable…

Hello Mats, I'm working on

Hello Mats,

I'm working on the legs for InMoov right now. Until now I have been using the DIY Servo in a very basic way, but I would like to know if the DIY Servo is compatible with the enable and disable function?

autoEnable / autoDisable

Hi Gael

Not currently. But the intention is that you should be able to replace any Servo with DiyServo.

/Mats

Hi ! There is a thing to

Hi ! There is a thing to check to look forward, I stuck on something. ( with my hardware )

The targetPos is never reached, currentPosInput ( potentiometer state ) is few degres up or down ( getCurrentPosInput() ).

It is transparent if we don't look at it.

Seem pid missing a little thing when it is near the position goal ( I played with it, no success,final exact position never reached ).

In this exemple I asked 90 input pos, and final pos is stucked near 96.

Some ideas guys ?